Is minic a úsáidtear giaranna boga nuair a dhéantar comhpháirteanna íogair nó tanaí a mheaisíní a d'fhéadfadh a bheith dochar do ghéaga crua traidisiúnta. Cuidíonn ábhar bog an fhód le fórsaí clampála a dháileadh go cothrom agus laghdaíonn sé an baol saobhadh nó damáiste don phíosa oibre. Is iondúil go n -úsáidtear giaranna boga freisin nuair a bhíonn codanna neamhrialta nó comhchruinnithe á gclampáil go neamhrialta.

Ar an láimh eile, déantar gialla crua as ábhar níos deacra. Baintear úsáid as giaranna crua chun clampáil agus daingniú a dhéanamh ar phíosaí oibre a dteastaíonn fórsaí clampála níos airde nó tacaíocht níos déine uathu. Is iondúil go n -úsáidtear iad chun comhpháirteanna soladacha, láidre a mheaitseáil ar féidir leo an brú a chuireann na giaranna i bhfeidhm a sheasamh.

Paraiméadar méide

| SPEIS. | S-1 | S-2 | S-3 | S-4 | S-5 | S-6 | S-7 | S-8 | S-9 | S-10 | Páirc chíor | Meáchan kg |

| 110 | 52 | 22 | 22 | 8 | 4 | 16 | 14 | 15 | 6.5 | 11 | 1.0x60 ° | 0.4 |

| 4 ' | 52 | 23 | 23 | 10 | 5 | 10 | 14 | 13 | 9 | 13.5 | 1.5x60 ° | 0.5 |

| 5 ' | 62 | 25 | 30 | 10 | 5 | 10 | 14 | 18 | 9 | 13.5 | 1.5x60 ° | 0.8 |

| 6 ' | 73 | 31 | 36 | 12 | 5 | 15 | 20 | 24 | 11 | 17 | 1.5x60 ° | 1.5 |

| 8 ' | 95 | 35 | 37 | 14 | 5 | 24 | 25 | 22 | 13 | 19 | 1.5x60 ° | 2.4 |

| 10 ' | 110 | 40 | 42 | 16 | 5 | 30 | 30 | 27 | 13 | 19 | 1.5x60 ° | 3.8 |

| 12p ' | 130 | 50 | 50 | 18 | 5 | 40 | 30 | 33 | 15 | 23 | 1.5x60 ° | 6.3 |

| 12h ' | 130 | 50 | 50 | 21 | 5 | 40 | 30 | 33 | 17 | 26 | 1.5x60 ° | 6.6 |

| 15p ' | 165 | 62 | 62 | 25.5 | 8 | 37 | 43 | 38 | 21 | 32 | 1.5x60 ° | 12.6 |

| 15h ' | 165 | 62 | 62 | 22 | 8 | 37 | 43 | 38 | 21 | 32 | 1.5x60 ° | 12.5 |

| 21 ' | 180 | 65 | 70 | 25 | 9 | 40 | 60 | 45 | 21 | 32 | 3.0x60 ° | 15.8 |

Paraiméadar méide

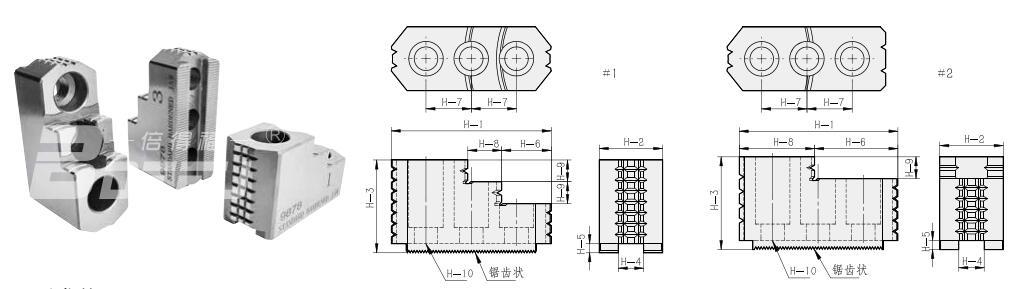

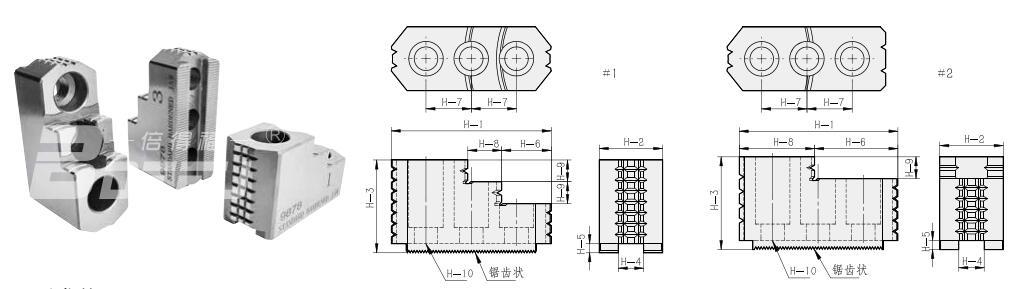

| SPEIS. | H-1 | H-2 | H-3 | H-4 | H-5 | H-6 | H-7 | H-8 | H-9 | H-0 | Páirc seire | Ualach | Líníocht retence |

| HJ-04 | 53 | 23 | 28 | 10 | 4 | 29 | 14 | 24 | 10 | M8x1.25p | 1.5x60 ° | 0.4 | Fig.2 |

| HJ-05 | 53 | 23 | 28 | 10 | 4 | 29 | 14 | 24 | 10 | M8x1.25p | 1.5x60 ° | 0.4 | Fig.2 |

| HJ-06 | 67 | 31 | 36 | 12 | 5 | 39 | 20 | 28 | 12 | M10x1.5p | 1.5x60 ° | 0.95 | Fig.2 |

| HJ-08 | 87 | 35 | 51 | 14 | 5 | 29.5 | 25 | 18 | 12 | M12x1.75p | 1.5x60 ° | 1.9 | Fíor.1 |

| HJ-10 | 101 | 40 | 54 | 16 | 5 | 45.5 | 30 | 18 | 13 | M12x1.75p | 1.5x60 ° | 2.8 | Fíor.1 |

| HJ-12 | 108 | 50 | 67 | 21 (18) | 4 (5) | 49 | 30 | 20 | 16 | M16x2p (M14x2p) | 1.5x60 ° | 3.5 | Fíor.1 |

| HJ-15 | 143 | 62 | 86 | 22 (25.5) | 8 (5) | 55 | 43 | 38 | 20 | M20X2.5P | 1.5x60 ° | 9.5 | Fíor.1 |

| HJ-18 | 143 | 62 | 86 | 22 (25.5) | 8 (5) | 55 | 43 | 38 | 20 | M20X2.5P | 1.5x60 ° | 9.5 | Fíor.1 |

| HJ-21 | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20X2.5P | 3x60 ° | 15.3 | Fig.2 |

| HJ-24 | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20X2.5P | 3x60 ° | 15.3 | Fig.2 |

| HJ-32 | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20X2.5P | 3x60 ° | 15.3 | Fig.2 |

| HJ-40 | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20X2.5P | 3x60 ° | 15.3 | Fig.2 |

Is iad na sonraí thuas na paraiméadair chaighdeánacha, is féidir réitigh phearsantaithe saincheaptha a sholáthar de réir riachtanas an chustaiméara.

Türkçe

English

Русский

繁體中文

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Māori

नेपाली

Oʻzbekcha

latviešu

Беларуская мова

Български

íslenska

Lietuvių