Mollis ora saepe usus est cum machining delicata aut tenuis-muratas partes, quae posset laedi per traditum dura ora. In mollis materia in maxillae adjuvat ad distribute clamping vires aequaliter et reduces periculum distortionem vel damnum ad workpiece. Mollis ora quoque communiter cum clamping irregulariter informibus et contumi partibus.

In alia manu, durum ora facta est a magis materiam. Durum ora adhibetur for clamping et securitate workpieces quod eget superiore clamping viribus vel rigidum firmamentum. Sunt typically propter machining solidum, robust components quod potest sustinere pressura operatur per ora.

Magnitudo modularis

| Spec. | S-I | S-II | S-III | S-IV | S-V | S-VI | S-VII | S-VIII | S-IX | S-X | Pix pice | Pondus kg |

| 110 | 52 | 22 | 22 | 8 | 4 | 16 | 14 | 15 | 6.5 | 11 | 1.0x60 ° | 0.4 |

| IV | 52 | 23 | 23 | 10 | 5 | 10 | 14 | 13 | 9 | 13.5 | 1.5x60 ° | 0.5 |

| V, | 62 | 25 | 30 | 10 | 5 | 10 | 14 | 18 | 9 | 13.5 | 1.5x60 ° | 0.8 |

| VI, | 73 | 31 | 36 | 12 | 5 | 15 | 20 | 24 | 11 | 17 | 1.5x60 ° | 1.5 |

| VIII, | 95 | 35 | 37 | 14 | 5 | 24 | 25 | 22 | 13 | 19 | 1.5x60 ° | 2.4 |

| X, | 110 | 40 | 42 | 16 | 5 | 30 | 30 | 27 | 13 | 19 | 1.5x60 ° | 3.8 |

| 12p ' | 130 | 50 | 50 | 18 | 5 | 40 | 30 | 33 | 15 | 23 | 1.5x60 ° | 6.3 |

| 12h | 130 | 50 | 50 | 21 | 5 | 40 | 30 | 33 | 17 | 26 | 1.5x60 ° | 6.6 |

| 15p ' | 165 | 62 | 62 | 25.5 | 8 | 37 | 43 | 38 | 21 | 32 | 1.5x60 ° | 12.6 |

| 15H | 165 | 62 | 62 | 22 | 8 | 37 | 43 | 38 | 21 | 32 | 1.5x60 ° | 12.5 |

| XXI, | 180 | 65 | 70 | 25 | 9 | 40 | 60 | 45 | 21 | 32 | 3.0x60 ° | 15.8 |

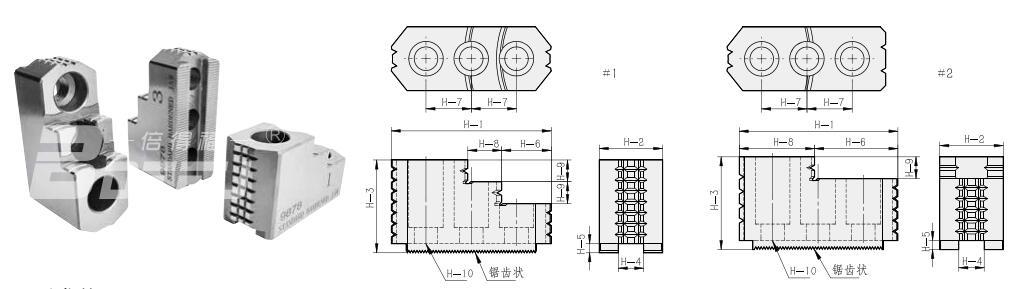

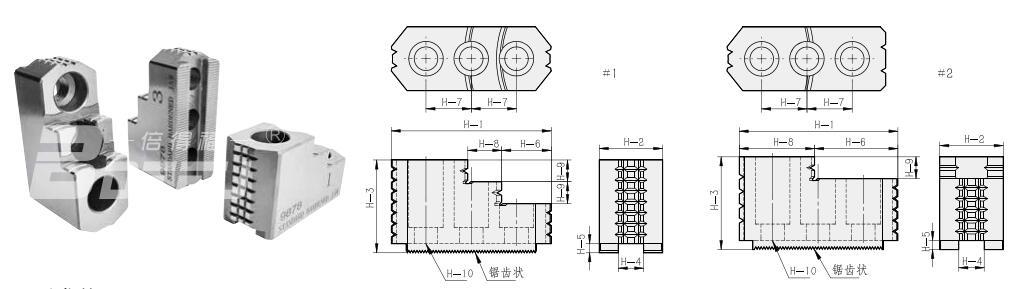

Magnitudo modularis

| Spec. | H-I | II-II | H-III | H-IV | H-V | H-VI | H-VII | H-VIII | H-IX | H 0 0 | Servatio picem | Pondus | Reterence |

| HJ-IV | 53 | 23 | 28 | 10 | 4 | 29 | 14 | 24 | 10 | M8x1.25p | 1.5x60 ° | 0.4 | Fig.2 |

| HJ-V | 53 | 23 | 28 | 10 | 4 | 29 | 14 | 24 | 10 | M8x1.25p | 1.5x60 ° | 0.4 | Fig.2 |

| HJ-VI | 67 | 31 | 36 | 12 | 5 | 39 | 20 | 28 | 12 | M10x1.5p | 1.5x60 ° | 0.95 | Fig.2 |

| HJ-VIII | 87 | 35 | 51 | 14 | 5 | 29.5 | 25 | 18 | 12 | M12x1.75p | 1.5x60 ° | 1.9 | Fig.1 |

| HJ-X | 101 | 40 | 54 | 16 | 5 | 45.5 | 30 | 18 | 13 | M12x1.75p | 1.5x60 ° | 2.8 | Fig.1 |

| HJ-XII | 108 | 50 | 67 | XXI (XVIII) | IV (V) | 49 | 30 | 20 | 16 | M16x2p (m14x2p) | 1.5x60 ° | 3.5 | Fig.1 |

| HJ-XV | 143 | 62 | 86 | XXII (25.5) | VIII (V) | 55 | 43 | 38 | 20 | M20x2.5p | 1.5x60 ° | 9.5 | Fig.1 |

| HJ-XVIII | 143 | 62 | 86 | XXII (25.5) | VIII (V) | 55 | 43 | 38 | 20 | M20x2.5p | 1.5x60 ° | 9.5 | Fig.1 |

| HJ-XXI | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20x2.5p | 3x60 ° | 15.3 | Fig.2 |

| HJ-XXIV | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20x2.5p | 3x60 ° | 15.3 | Fig.2 |

| HJ-XXXII | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20x2.5p | 3x60 ° | 15.3 | Fig.2 |

| HJ-XL | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20x2.5p | 3x60 ° | 15.3 | Fig.2 |

Et supra data sunt vexillum parametri, personalized customized solutions potest provisum secundum elit scriptor postulationem.

Türkçe

English

Русский

繁體中文

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Māori

नेपाली

Oʻzbekcha

latviešu

Беларуская мова

Български

íslenska

Lietuvių